The installation of Tyra II goes into the next round

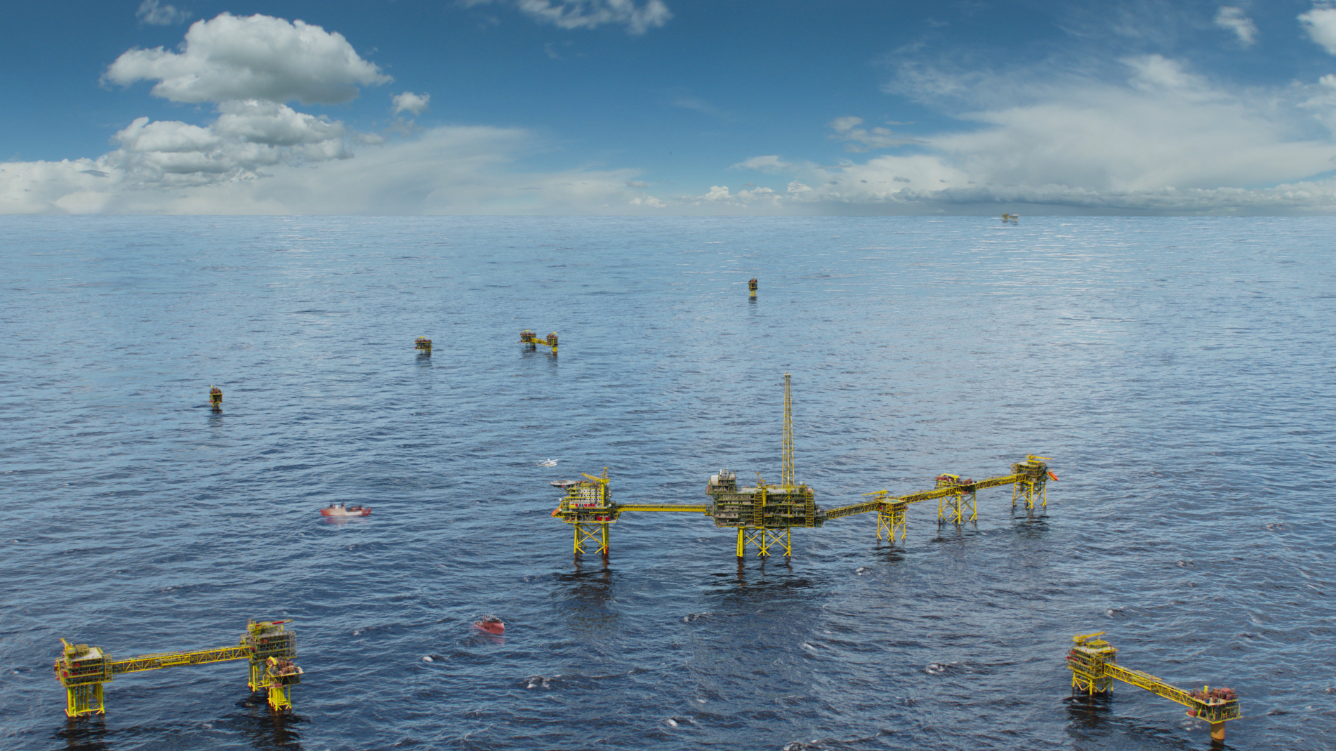

Esbjerg, 3 April 2022: TotalEnergies EP Denmark and its Danish Underground Consortium partners Noreco and Nordsøfonden are pleased to announce the successful start of this spring’s installation campaign at the Tyra field.

Today at 11:20, the two crane drivers on the world’s largest crane vessel, Heerema Marine Constractors’ Sleipnir, got the green light to install the first three out of six new Tyra II structures. Already at 17:20, they successfully set-down the final out of three 3,485 tons heavy well head and riser modules at Tyra West.

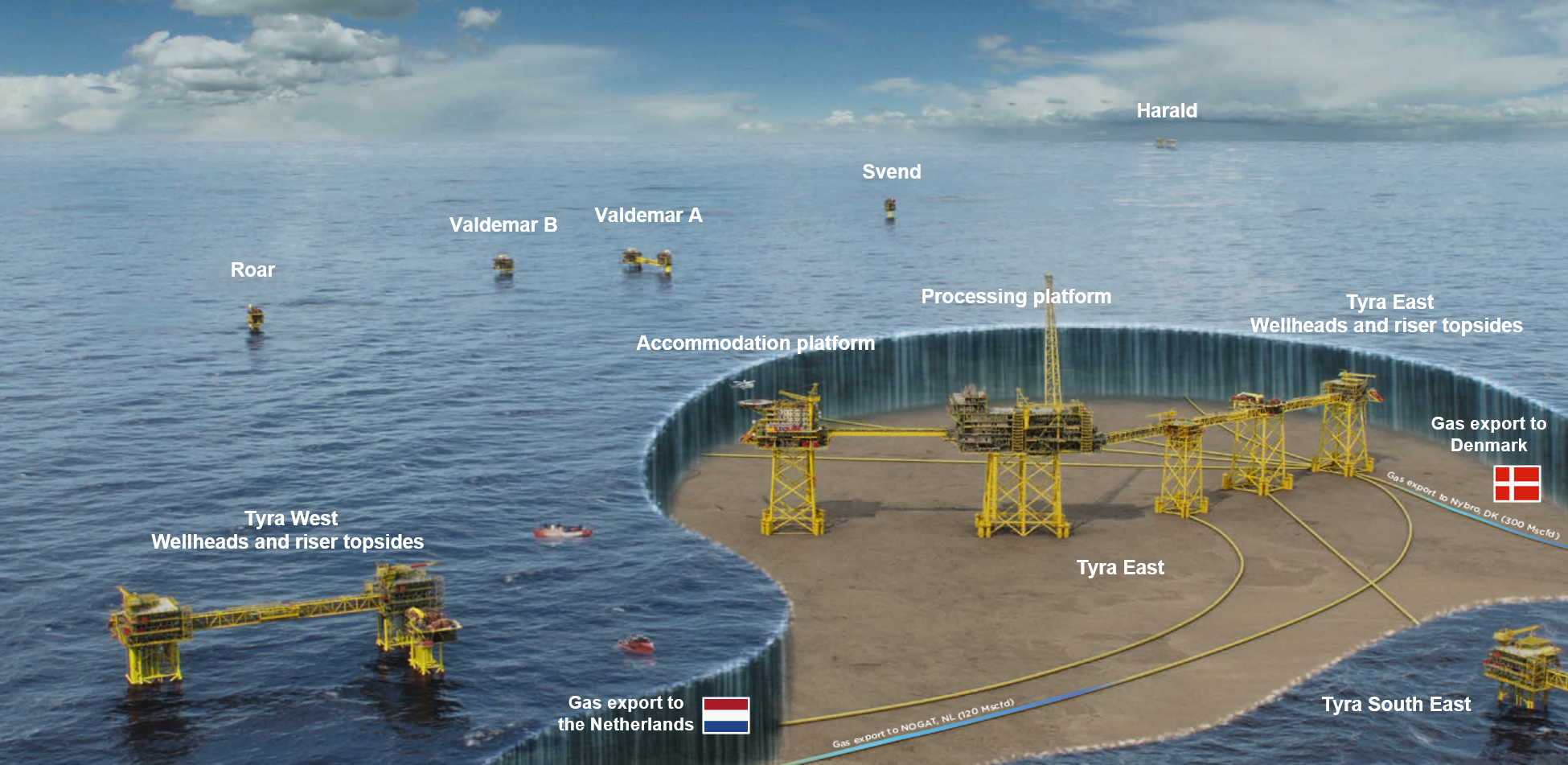

“With the installation of the well head riser modules for Tyra West, we are kicking off this spring’s lifting campaign. This will move us an important step closer towards the finalization of Tyra II – Denmark’s new high-tech hub for natural gas production. In the coming days, all platforms, except the processing platform, will have been installed in their final position. What might look like moving around toy blocks, is actually a highly complex task which requires years of preparation and the highest precision during the execution. Just like pilots before takeoff, our teams follow a very detailed and thoroughly prepared manual written by lifting and installation experts”, says Lars Bo Christiansen, Tyra Redevelopment Deputy Project Director for TotalEnergies EP Denmark.

The three Tyra West well head and riser modules have been lifted onboard Sleipnir after they arrived in Rotterdam during February. Here, they took a pitstop to await the optimal window for installation in the Danish North Sea during April.

On 30 March, Sleipnir embarked together with the modules and a 260-man crew on the 527 kilometers long journey to the Tyra field, where they arrived 48 hours later. Once the crew completed all final checks on the jackets and removed the sea-fastening from the modules, the lifting action was kicked off.

The duration of the installation campaign, including lifts as well as subsequent reassembling and welding, will last approximately 2 weeks. In total, Sleipnir lifts two bridges and four modules which include the three well head and riser modules and the new Tyra II utility and living quarters.

– Access visuals of the installation campaign here.

Facts about the installation

- 260 people are onboard Sleipnir to execute the lifting of four modules and two bridges within two weeks – the modules being lifting into their final position are the utility and living quarters as well as the three Tyra West well head and riser modules.

- Sleipnir is the world’s largest crane vessel from our EPC contractor Heerema Marine Contractors, and its two huge cranes can lift a weight of up to 20,000 tons. The vessel is 220 meters long and 102 meters wide – a size equivalent to approximately 3 football fields.

- Sleipnir has already been part of the Tyra removal campaign and helped install both the new jackets in September 2020 as well as the first new Tyra II modules in September 2021.

Well head and riser modules for Tyra West

- The three brand-new wellhead and riser modules weigh together 3,485 tons. They were installed one after another by Sleipnir within only 6 hours.

- The crane operators will lower the modules down over so-called guide pins spanning only 1 meter in diameter. Hitting those straight on is crucial to avoid the risk of damaging the existing well pipes and jackets which are reused in the new design.

Tyra II utility and living quarters

- The Tyra II utility and living quarters module consists of seven levels with a helideck at the top, weighs 5,584 tons, and is 32.5 meters tall– equivalent to the height of the Esbjerg Water Tower. This module will be the heaviest to be lifted into final position at the Tyra field during this spring’s lifting campaign.

- The two 2.1 meter high and 1.7 meter in diameter wide stabbing cones which are placed on the bottom of the utility and living quarters, will help the crane drives to lift the module precisely on the jackets.

- In the future, the crew on Tyra II will stay even more safe as the processing platform and utility and living quarters are separated by an 85-meters-long bridge in the new field design. Moreover, the module’s design is focused on safety, efficient workflows, and general well-being. It is equipped with three lifeboats and the three fire pumps are able to deliver 8,250,000 liters water per hour – equivalent to the average daily water consumption of 1.8 million Danes (when calculated with a consumption of 106 liters per person per day)