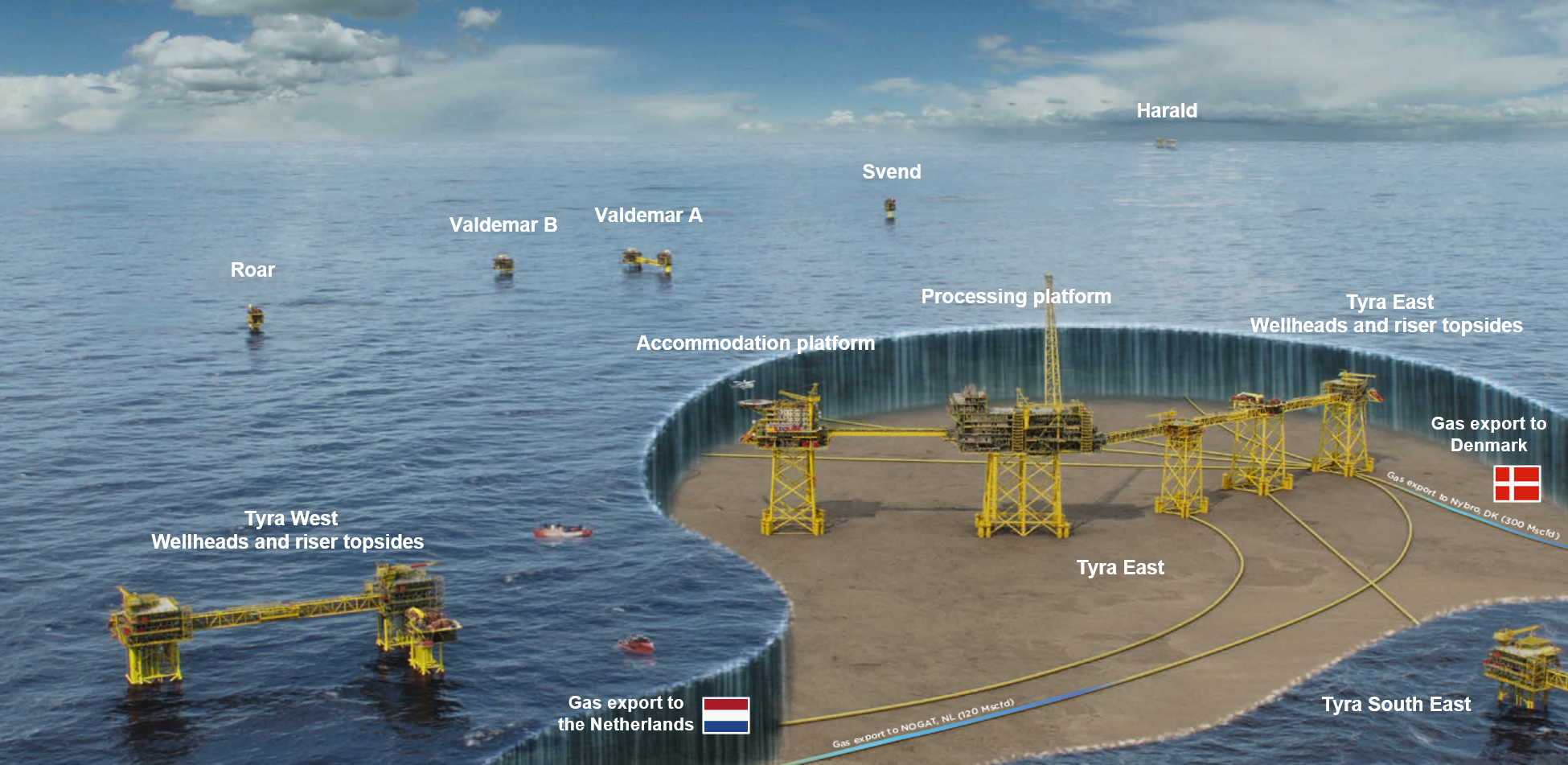

The build-up of one of the world’s most advanced gas fields starts now in the Danish North Sea

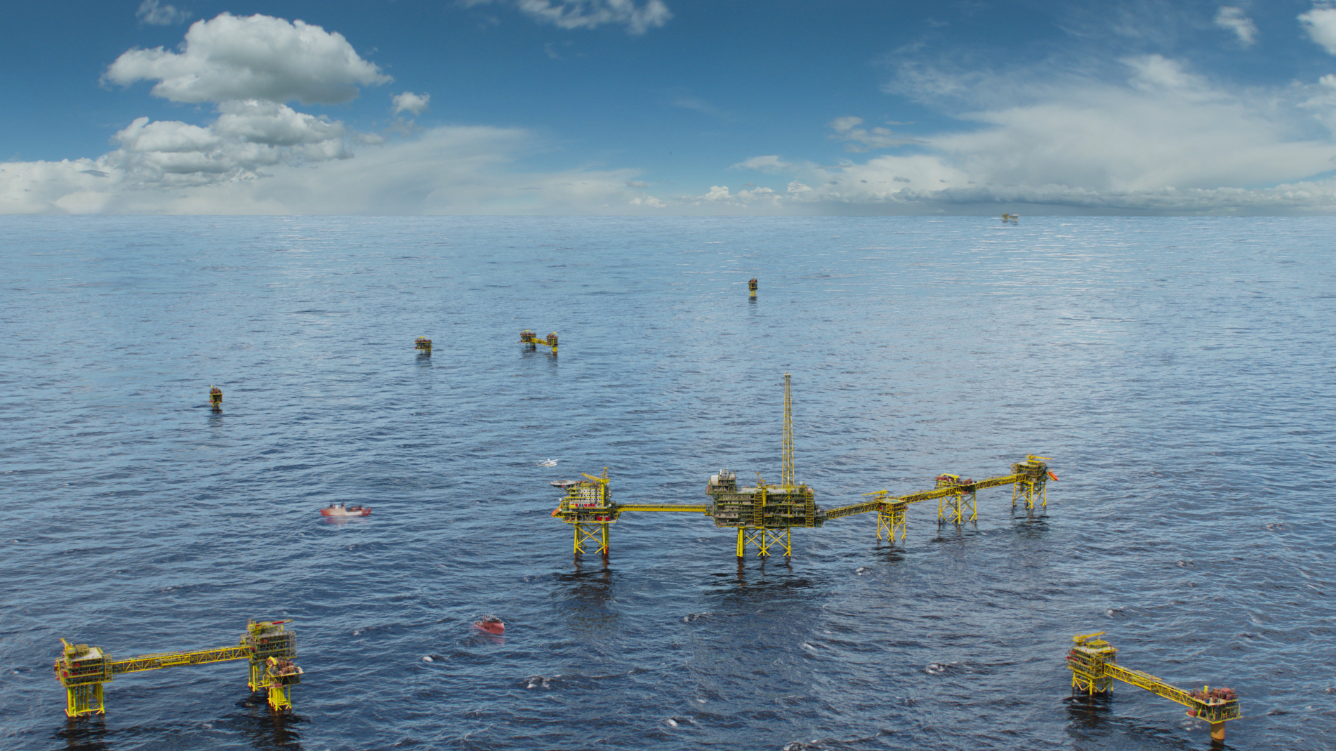

Today, the build-up of Denmark's new high-tech hub for natural gas begins - the modernized Tyra II. The world's largest crane vessel, Sleipnir, lifts the first new Tyra II topsides in place 225 km west of Esbjerg at the Tyra field in the Danish North Sea.

Three production topsides weigh up to 2,600 tons and two bridges traveled almost 16,000 kilometers from Singapore through the Suez Canal, and will be installed at the Tyra field during the coming weeks.

Focus on sustainability

The three production topsides that just landed at the Danish North Sea, are two so-called wellhead topsides and one riser topside. From the production platforms the wells are running into the reservoir, and it’s here the natural gas flows into Tyra II.

Since the start of the project, it has been an essential prerequisite for to focus on sustainability in all aspects of the redevelopment. For example, the 3-meter tall 44 wellheads have been refurbished and modernized by local companies in Esbjerg. The wellheads were installed on Tyra in 1984, and even after almost 40 years in operation, they are in such good condition, that they can be reused

In addition, the jackets and wells are also reused rather than producing and installing new ones. Thereby, resources and emissions are saved with regard to decommissioning, transportation, production, and re-installation.

Precision is a keyword for the installation

It is an impressive and enormous lifting operation combined with millimeters of precision, which is now underway in the North Sea’s winds and waves.

The production topsides will individually be lifted about 50 meters up from the transport ship and installed with great accuracy on the jackets in the North Sea. This is done with the world’s largest crane vessel, Sleipnir, which is 220 meters long, an equivalent of the length of more than 4 Olympic swimming pools. The operation is carried out in five lifts over a week.

The three production topsides weigh up to 2,600 tons, corresponding to almost 15 jumbo jets. Lifting the topsides off the vessel and onto the jackets in the North Sea requires enormous precision. At a depth of 40 meters and with the heavy topsides hanging in a crane, the operator on Sleipnir must lower the topsides down over a so-called guide pins spanning only 1 meter in diameter. Hitting those on straight is crucial as we otherwise risk that well pipes get damaged

Morten Hesselager Pedersen, Vice President, Head of the Tyra Redevelopment for TotalEnergies EP Denmark.

The duration of the installation campaign including lifts as well as subsequent reassembling and welding lasts approximately 3-4 weeks. After this, a large work scope begins to connect it all. Technology, pipes and parts must be assembled, put into operation and tested – a large number of local Esbjerg companies are responsible for this part. The remaining 5 out of 8 new topsides will arrive at the Tyra field in 2022, where they will be installed prior to production start in June 2023.

The continuation of Denmark’s first natural gas

Tyra started production in 1984 but was temporarily shut-in in 2019 due to the redevelopment and modernization of the field and platforms. Tyra II will be the new high-tech hub for Danish natural gas and reduce CO2 emissions by 30%.

When production of Tyra II resumes in June 2023, a continued production of natural gas is secured for at least 25 years. Thus, Tyra II becomes a central part of the Danish energy infrastructure by offering more affordable, clean and reliable energy, which both Denmark and Europe needs in the transition towards a low-emission society.