Tyra II will give us a glimpse into the future

Tyra II will be one of the world’s most technologically advanced natural gas fields, where digitization will set new standards for production optimization, CO2 reduction and maintenance of Denmark’s newest gas field.

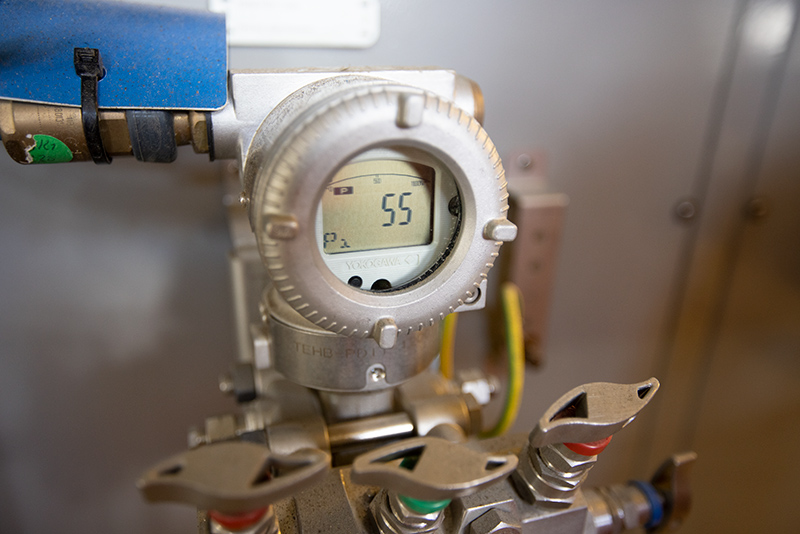

More than 100,000 data points from sensors located throughout the platform in the North Sea will enable us to follow the engineering, production, and individual parts - basically every single aspect of the large production field.

The purpose is to get the best look into the future and use this information to predict events before they happen. This is crucial to safety and for the sake of the environment.

– We are able to monitor the condition and performance of the North Sea equipment in the field, around the clock. “This is a huge digital insight into the entirety of engineering and production. Pumps, valves, heat exchangers, pipes, electrical panels, etc. all the way down to the smallest parts,” says Ole Munk, Head of Maintenance and Inspection for Tyra Reconstruction at TotalEnergies EP Danmark.

Sensors on the equipment measure more than 100,000 data points on Tyra II. They make it possible to register even the smallest changes in the North Sea from the onshore control room in Esbjerg. From here, you can intervene remotely from the shore or via the personnel on the platform.

We try to predict the future by catching incidents and events before they happen”

Ole Munk, TotalEnergies EP Denmark

From the Northsea to the control room in Esbjerg

Data points

0

Predictive maintenance

One of the main objectives is to make daily operations and maintenance more efficient. This reduces emissions.

“We try to predict the future by catching incidents and events before they happen. Instead of a valve or a pump running until it breaks down, sensors detect the smallest changes, and we can intervene before things stop working or break down,” says Ole Munk.

Together with engineers Jan Thordtsen Zaar and Ulrik Thomsen, he is responsible for bringing all the data points on Tyra II to life and utilizing them.

Computers get to know Tyra II

This significantly reduces maintenance and the environmental impact related to replacing equipment, preventive measures, and transport of technicians.

“Most people are probably familiar with this in relation to their cars, which have service intervals that specify taking it to the workshop every 30,000 km, for example. This is also the case with a lot of equipment on a platform. The problem is that every time you tinker with things, there is a risk of a breakdown. This requires resources, so it is much more efficient and environmentally friendly to move away from a fixed schedule and instead use digitization to predict exactly when a piece of equipment will require attention,” explains Ulrik Thomsen, Chief Engineer for Tyra Reconstruction at TotalEnergies EP Danmark.

With continuous data input, computers “learn” exactly how a specific part on Tyra II works, which allows for predictive maintenance or repairs. One such example is protecting pipe sections and containers against corrosion, which in the past depended on inspection and treatment at fixed intervals and is now regulated digitally. Sensors and computers now determine the need, which reduces the use of protective gear and thus the environmental impact.

It would even have been possible to equip the filter for the coffee machines with a sensor

Jan Thordtsen Zaar, Chief Engineer

Only do things when necessary

“Digitization means that we can step back, cross our arms and only do things when they are actually necessary,” explains Ulrik Thomsen, adding:

“This more efficient digital maintenance and operation saves resources and helps reduce emissions from Tyra II’s production by up to 30 per cent. It is also our experience that if you manage to fix equipment before it breaks down, it is up to 50 per cent cheaper to repair.”

Digitization is also a crucial factor when it comes to safety.

Breakdowns, repairs and stoppages in production are always critical, but when you are 225 km out in the North Sea, they are really critical; not only because it takes a lot of resources to get specialists out to the platform, but also because it increases the risk of accidents. That’s why it’s a huge gamechanger to be able to control things digitally without having to intervene physically

Breakdowns, repairs and stoppages in production are always critical, but when you are 225 km out in the North Sea, they are really critical

Jan Thordtsen Zaar, Chief Engineer

Coffee filter sensor

When Tyra II is put into operation in June of 2023, the many sensors and data points will have to spend time “getting to know” the platform. However, as computers and algorithms receive data and registrations, they will become smarter and more accurate in their predictions about the future.

In theory, sensors can be attached to, and data collected from, all of the equipment, devices and technologies used in production. However, it was quickly decided to set some limits, as Jan Thordtsen Zaar explains:

“It would even have been possible to equip the filter for the coffee machines with a sensor, but that was probably taking things a bit too far,” he explains with a smile.

Facts

What is a condition and performance monitoring system?

CPMS Condition & Performance Monitoring System

The equipment on Tyra II is divided into 29 parent categories, which include

- Mechanical equipment such as: Compressors/turbines/valves/heat exchangers

- Electrical equipment (transformers/motors/switchboard components, magnetic bearings)

- Pipe sections and vessels

How is the equipment monitored?

- Vibrations

- Changes in temperature, pressure, flow, time, performance, etc.

- Infrared scanning

- Alarms